The most important facts in brief

Industrial mechanic (m/f/d)

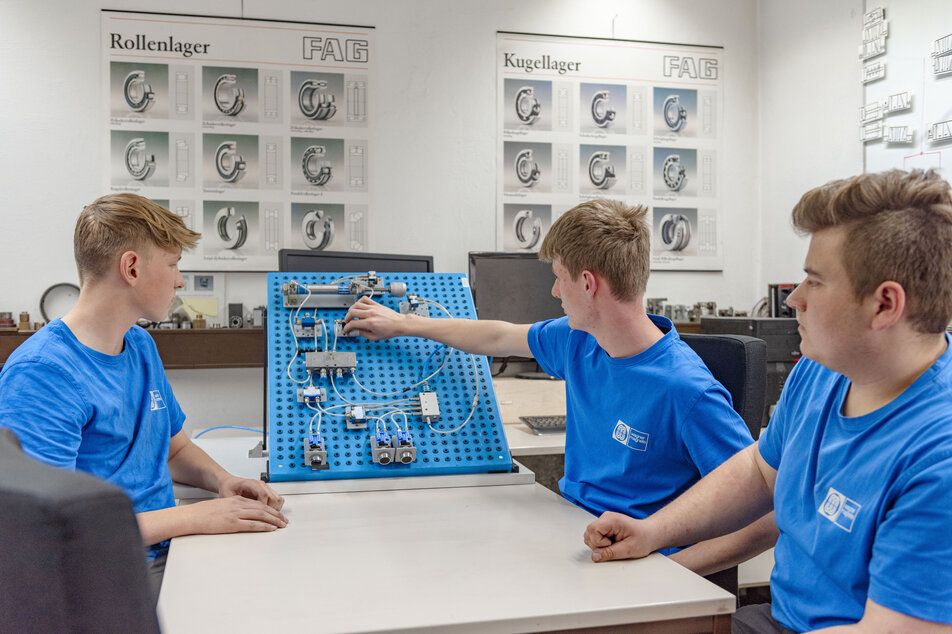

At WAGNER MAGNETE, we combine decades of tradition with the pulse of modern technology. As a pioneer in magnet technology, we set standards in innovation and quality. If you would like to become part of this exciting field, an apprenticeship as an industrial mechanic could be just the thing for you.

During your training with us, you will immerse yourself in the world of magnet technology and learn about the many facets of the industrial mechanic profession. Our experienced employees will accompany you, pass on their knowledge to you and act as mentors. From planning and production to the maintenance of complex magnet systems, you will gain in-depth insights into all process steps.

At WAGNER MAGNETE, you can expect not just an apprenticeship, but a real career perspective. Our trainees are our most valuable asset and we are proud to support you in your development and give you the tools for a successful future in the industry.

Join us in the fascinating world of magnet technology and actively shape your future!

What are industrial mechanics (m/f/d)?

- Production of components and assemblies based on technical drawings

- Assembly and disassembly of machines and systems

- Commissioning and maintenance of technical systems

- Carrying out measurements and tests

- Repairing machines and systems

- Optimisation of work processes

Training duration and requirements

Training as an industrial mechanic usually takes 3.5 years and is a dual programme, i.e. trainees acquire both theoretical knowledge at vocational school and practical experience at the training company. In order to start the apprenticeship, a successful secondary school leaving certificate or a secondary school leaving certificate is usually required. In addition, prospective industrial mechanics should have good hand-eye coordination, technical understanding and skill and be able to work in a team. Knowledge of maths and spatial awareness are also an advantage in this profession.

During their training, trainees will learn how to manufacture components and assemblies, assemble plants and systems, maintain and service machines and plants and analyse and rectify faults. The programming of control systems and the optimisation of production processes can also be part of the training content.

Overall, training as an industrial mechanic provides a solid basis for a successful career in the metal and electrical industry and opens up numerous career prospects.

Prospects after the apprenticeship

The prospects after training as an industrial mechanic are varied and offer good prospects for the future. On the one hand, you can enter the profession directly after training and work as a specialist in industrial companies. This gives you the opportunity to develop further within the company, for example by taking on team management tasks or further training to become a technician or master craftsman.

On the other hand, there are also opportunities to specialise or undertake further training after the apprenticeship. For example, you can complete further training to become an industrial foreman and take on management tasks. Further training to become a technician or engineer is also possible and opens up further career opportunities.

If you are interested in a career in research and development, you can also consider studying mechanical engineering, mechatronics or similar disciplines.

Overall, the profession of industrial mechanic offers good prospects and career opportunities in various areas of industry.