HIGHLIGHTS & ADVANTAGES

MAGNETIC TAPE ROLLS

MAGNETIC TAPE ROLLS

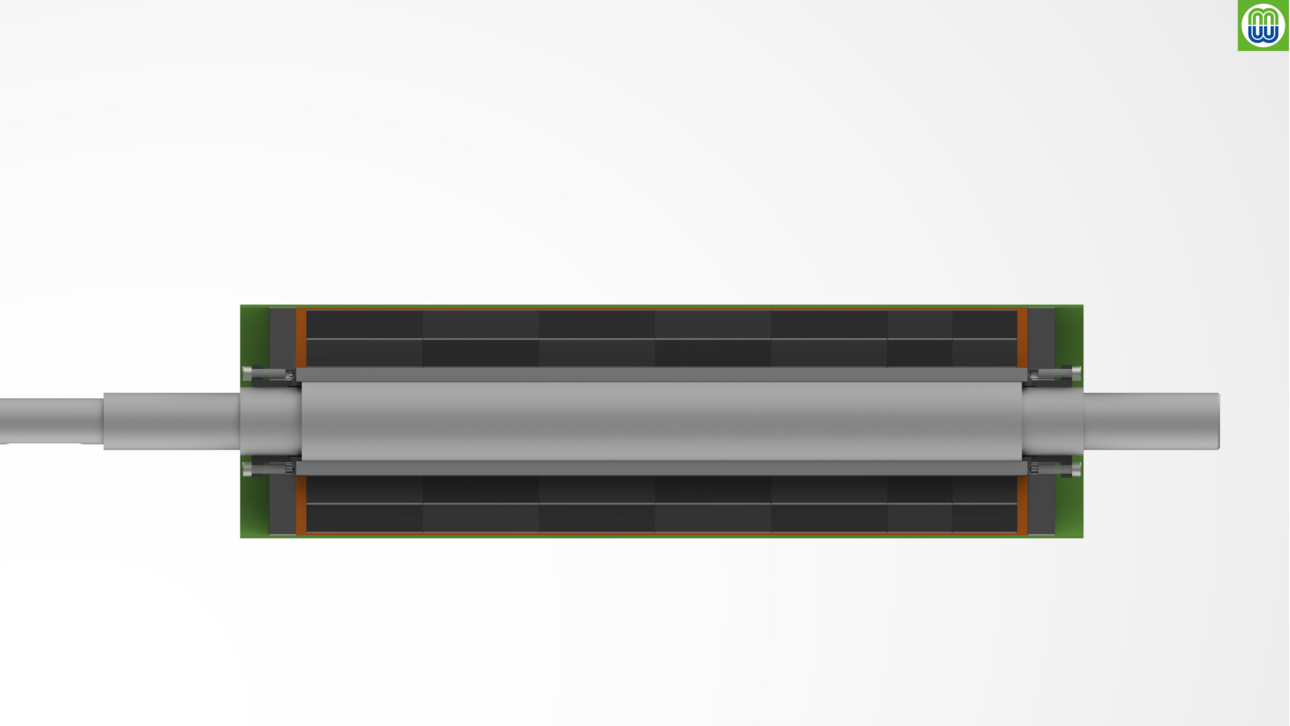

We adapt the shaft dimensions and the strength of our magnets to our customers' applications.

Belt rollers are a simple but efficient addition to overbelt magnets and can be built in many different diameters and working widths.

Functional principle

HOW DO magnetic tape rolls WORK?

Extremely robust

Non-magnetic area

At WAGNER MAGNETE, magnetic tape rolls are designed to guarantee maximum efficiency and maximum yield. To achieve this, it is important that the magnetic area is not affected by magnetisable materials.

By using non-magnetic materials in the area marked in grey, an optimum effect of the magnet can be ensured. The hatched area has a diameter that corresponds to twice the diameter of the roller. No magnetic field emerges at the ends of the roller, which ensures a smooth material flow.

This design eliminates material jams and problems with iron discharge, ensuring reliable and effective separation.

Neodymium magnets for high demands

For demanding applications, WAGNER offers magnetic tape rolls with particularly strong neodymium magnet material. These magnets guarantee a high degree of separation, even with less magnetisable steel parts and when separating the smallest iron parts. Neodymium magnets are characterised by their extremely high attractive forces at close range.

Please note, however, that the maximum temperature range of neodymium magnets is 80°C as standard. We also have special neodymium magnets for higher temperatures, but these are not a standard offering. If you require magnets for higher temperatures, we can offer you the appropriate options.